Lorem ipsum dolor sit amet, consectetur adipiscing elit. Est euismod gravida amet, sapien in.Est euismod gravida amet, sapien in.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Est euismod gravida amet, sapien in.

Wood is the sustainable building material of the future. We need to use wood as a construction material instead of concrete and steel to reduce the global greenhouse gas emissions.

Cross Laminated Timber (CLT) elements are the most effective material to ensure sustainable construction methods are achieved. Designed with geographical climate impacts in mind, solid wood buildings can last for centuries. Wood has the ability to absorb and release moisture and is resistant to many of the chemicals and extreme climate variances.

Assembling of CLT is quick and easy due to simple and standardized connection process between elements. There is no need to wait for curing of connections, thus enablin50% faster construction time than concrete or steel.

Wood is 5-6 times lighter than reinforced concrete, thus it requires less transportation units to deliver the materials to building site.

Buildings generate nearly 40% of annual global CO2 emissions. Of those total emissions, building operations are responsible for 28% annually, while building materials and construction (typically referred to as embodied carbon) are responsible for an additional 11% annually.

By replacing concrete and steel with CLT, we can reduce the CO2 gas emissions in building industry.

Usage of CLT decreases wet processes in construction, thus reducing the time and costs related to drying of the building.

Wood is 5-6 times lighter than reinforced concrete, thus lighter foundations are required for the building and smaller lifting mechanisms, i.e. cranes, are required.

Wood is a natural insulator due to air pockets within its cellular structure, which means that it is 15 times better than masonry, 400 times better than steel, and 1,770 times better than aluminum.

Building codes require all building systems to perform to the same level of safety, regardless of the material used.

CLT construction has a proven safety and performance record for fire protection, and the addition of sprinkler systems, fire-resistance-rated wall and floor assemblies can be used to safely increase the allowable size of solid wood structures.

High winds, hurricanes and earthquakes are a harsh reality for some of European geographical locations. Solid wood buildings can be designed to withstand high winds and earthquakes given these characteristics.

Wood has the ability to absorb and emit humidity according to the fluctuations that exist in the house. This improves the air quality significantly which is of great importance for a good indoor climate.

Architects love to use wood for many reasons, including cost, ease and efficiency of construction, design versatility, and sustainability—as well as its beauty and the innate appeal of nature and natural materials. Innovative new technologies and building systems leads to the increased use of wood as a structural material in private houses, schools, residential buildings, and offices.

Modern production facilities allow the CLT elements to be exclusively produced in a project-related way. On the basis of approved production plans, the elements are cut using state-of-the-art CNC systems.

The elements are delivered directly to the construction site on a timely basis, either by lorry or in a container.

CLT production begins with timber selection. C24 strength graded spruce/pine are selected and defects removed.

Timber is cut to necessary length and arranged in layers.

The surface is bonded with a polyurethane adhesive (PUR). The formaldehyde-free adhesives that we use do not pose a health hazard and the quantities are reduced as far as possible in compliance with the necessary requirements resulting in a very low proportion of glue – 1%.

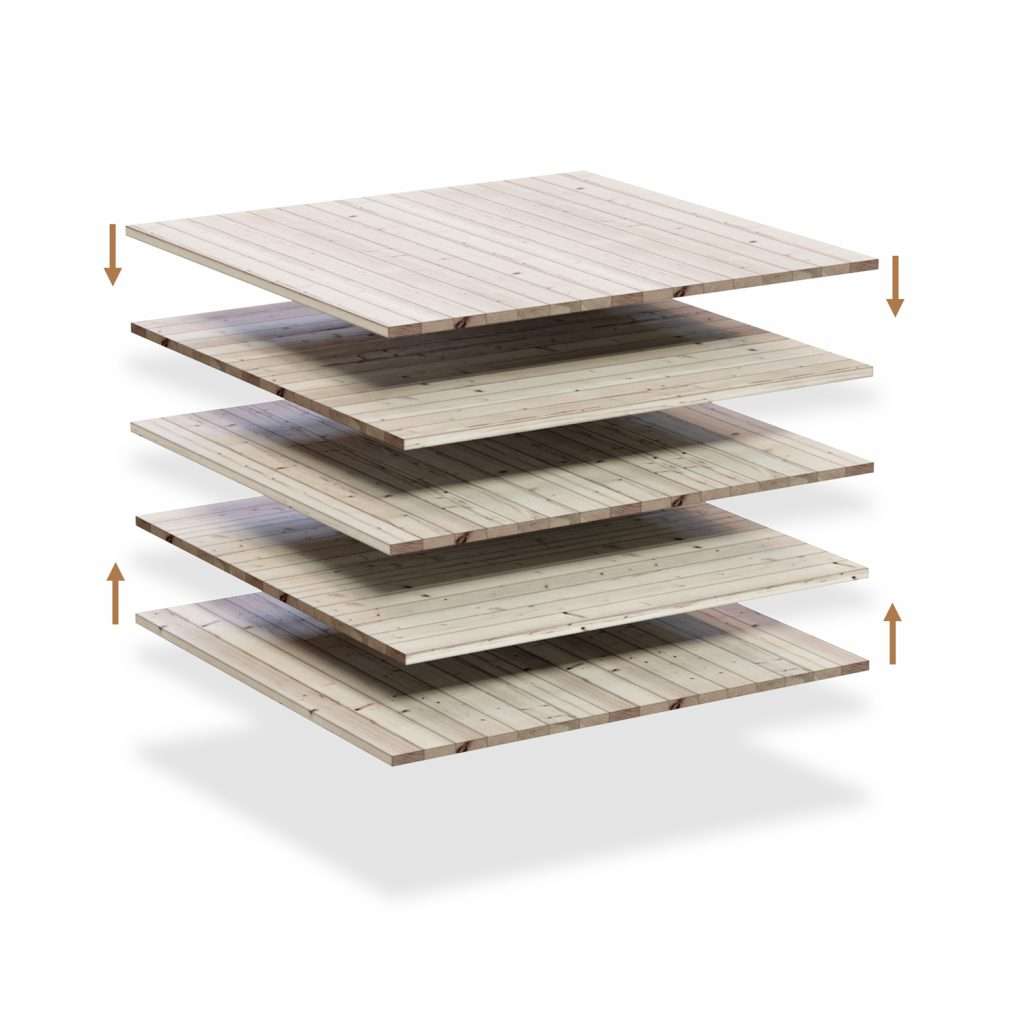

Layers get stacked up and arranged at perpendicular angles to each other, after which a press bonds the elements into a solid panel – which we call “Master panel”. It takes 30 minutes to complete the pressing and curing process.

With the Master panel ready, it can proceed to the CNC machine. A digital design is used to cut out the necessary measures and openings, pre-drill holes and any other fabrication requests with the highest precision. All of which is followed by thorough quality control.

Highest-possible freedom in architectural implementation. CLT panels are perfectly suited for load-bearing, reinforced and non load-bearing wall, ceiling and roof elements.

CLT panels provide healthy, comfortable room climate. Best utilisation of the building area and achievable Gross Leasable Area by using slim construction CLT panels.

Quick and dry construction period, thus quick readiness for occupancy. CLT panels are highly accurate because of high precision CNC-controlled cutting.